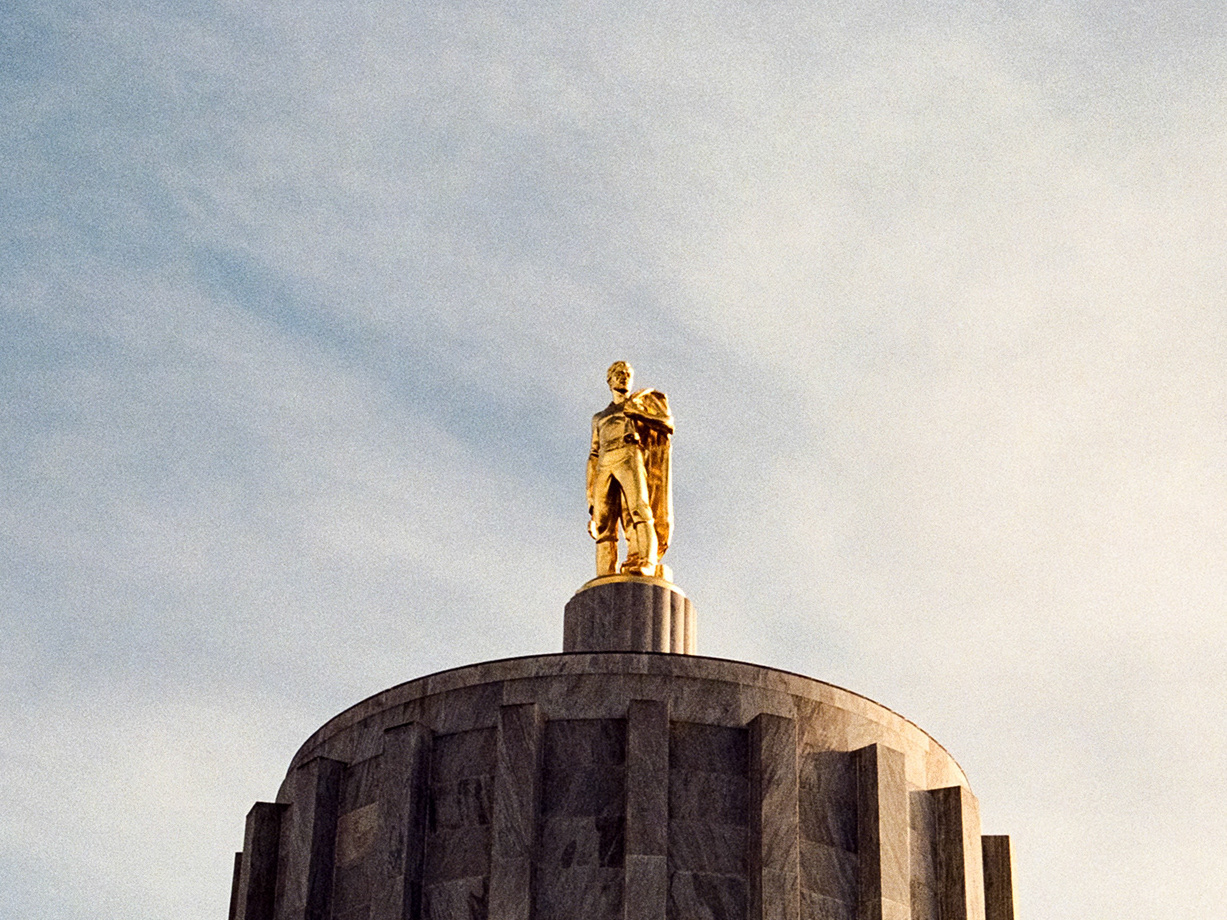

This project was my year 12 major work for Industrial Technology - Timber. The project aim was to design and build a custom piece made from timber. I decided to make a coffee table with American Oak.

This project developed both my manufacturing and design skills and inspired my interest in pursuing a career in industrial design.

Design Development

The curved edges of the coffee table were a central part of the design and are tied in with the other features, such as the round legs.

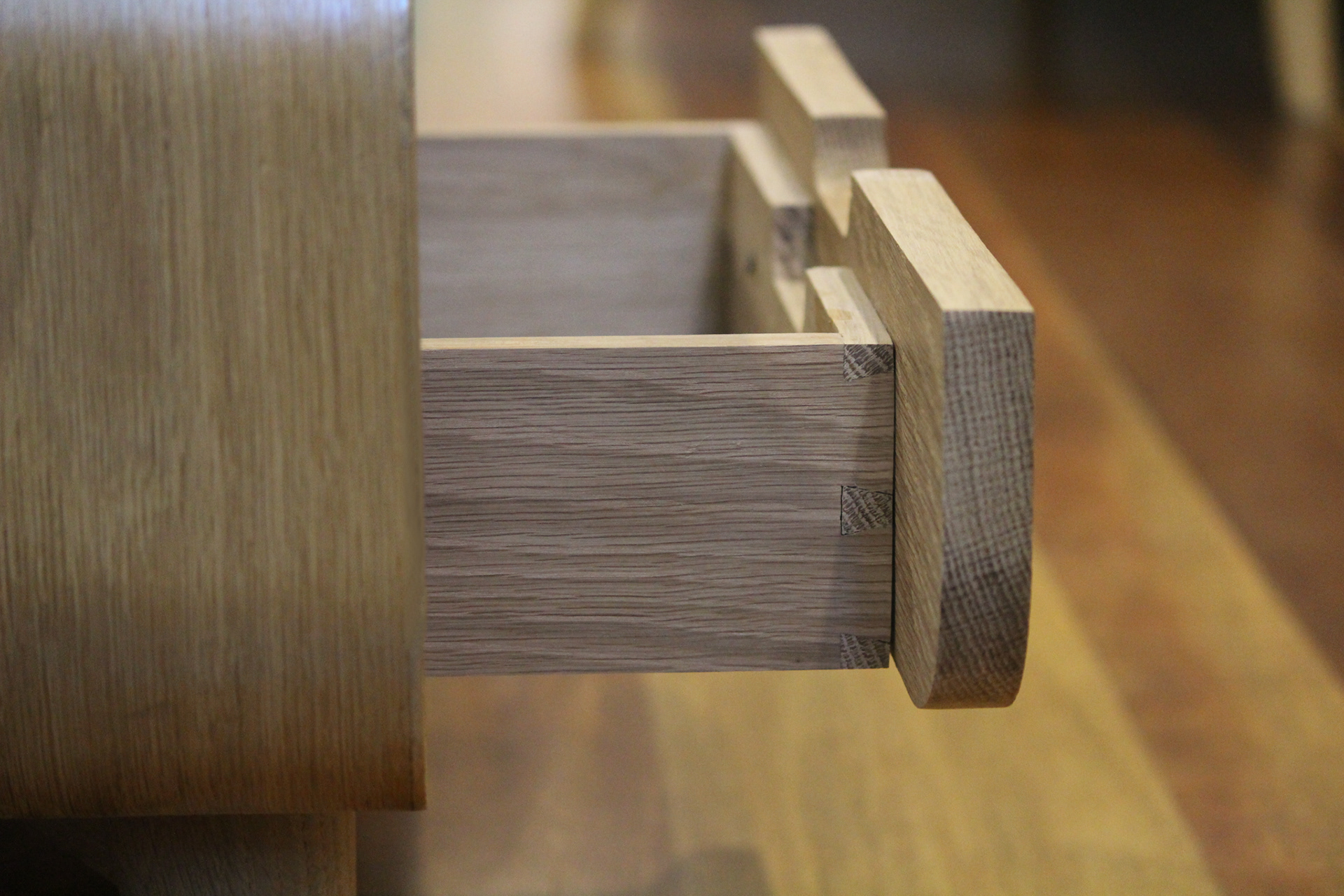

Drawer construction

The drawers were made with hand cut dovetails for aesthetic and strength. To cut the handles I made a form and used a router to cut it out accurately.

Legs

The legs were cut on the lathe, tapered towards the ends. I constructed a jig for the legs which cut them on a slant to achieve the correct angles.

Kerf bending

The curved edges took a few different tests to get the result I wanted. I found that Kerf bending achieved the result I wanted. I tested different thickness of cuts and width between them. I made a few different iterations of forms to be able to get an accurate and square bend.

Once the form was ready I clamped the timber to the form and filled the gaps with epoxy. I then glued the next piece on and clamped it down to the form. I repeated this for all the pieces until I had both sides set. There was a lot of clean up to get them looking right and perfectly square.

Glue up and internal parts

To connect the table top to the curved edges I used a half lap joint and added dowels for extra strength. I made a quick jig to for drilling the holes to be able to line them up much easier. To the right are some images of the glue up and edge banding application.

Edge banding and clean up

Final Table

Renders